Fiberglass repair in collision restoration requires understanding its unique composition of glass fibers reinforced with polyester or epoxy resin. Technicians assess damage using specialized methods and select appropriate repair compounds for meticulous restoration, preserving both aesthetic and structural integrity. Visual and functional assessments during inspection guarantee structural integrity and optimal performance. Rigorous quality assurance post-repair ensures durability, visual excellence, and real-world functionality, restoring vehicles to top-tier condition.

After a collision, proper fiberglass repair ensures vehicles return to their pre-accident condition. This in-depth guide explores the meticulous process of inspecting repairs following fiberglass collision restoration. We delve into understanding the unique composition of fiberglass, examining visual and functional aspects during inspections, and implementing quality assurance measures for lasting durability. By mastering these techniques, shops can deliver top-tier fiberglass repair outcomes, restoring vehicles to their vibrant pre-collision state.

- Understanding Fiberglass Composition for Effective Repairs

- Inspection Techniques: Visual and Functional Assessments

- Quality Assurance: Ensuring Longevity After Collision Restoration

Understanding Fiberglass Composition for Effective Repairs

Fiberglass, a composite material renowned for its strength-to-weight ratio, is commonly used in automotive body work and classic car restoration projects. Understanding its unique composition is paramount when undertaking fiberglass repair collision restoration. This lightweight yet robust material consists of a matrix of glass fibers impregnated with a resin, typically polyester or epoxy. The intricate structure offers exceptional structural integrity while allowing for complex shapes and designs, making it a popular choice in the automotive industry.

When conducting repairs, it’s crucial to assess the extent of damage, which may include cracks, breaks, or delaminations in the fiberglass. Skilled technicians employ various techniques, such as grinding, sanding, and wet sanding, to prepare the damaged area for repair. The goal is to ensure a smooth surface that allows for proper adhesion of the selected repair compound, whether it’s a putty, filler, or composite material tailored for fiberglass restoration. This meticulous process, combined with an understanding of the fiberglass composition, enables experts to expertly restore vehicles to their pre-collision condition, preserving the aesthetic and structural integrity of both modern and classic automotive body work and vehicle paint repair projects.

Inspection Techniques: Visual and Functional Assessments

During the inspection phase of fiberglass collision restoration, shops employ a combination of visual and functional assessment techniques to ensure the highest quality repairs. Visual inspections involve a thorough examination of the vehicle’s bodywork using high-resolution cameras and intense lighting to uncover any hidden damage or imperfections. This meticulous process includes checking for cracks, dents, and variations in paint finish that might be missed at first glance.

Functional assessments, on the other hand, go beyond aesthetics to test the integrity and performance of the repaired fiberglass components. This involves dynamic testing such as stress and strain analysis, water immersion tests, and simulation of real-world driving conditions. These functional checks guarantee that the vehicle’s structural integrity, aerodynamics, and safety systems are fully restored and operating optimally, ensuring a seamless blend of aesthetics and performance in the final automotive restoration or car damage repair.

Quality Assurance: Ensuring Longevity After Collision Restoration

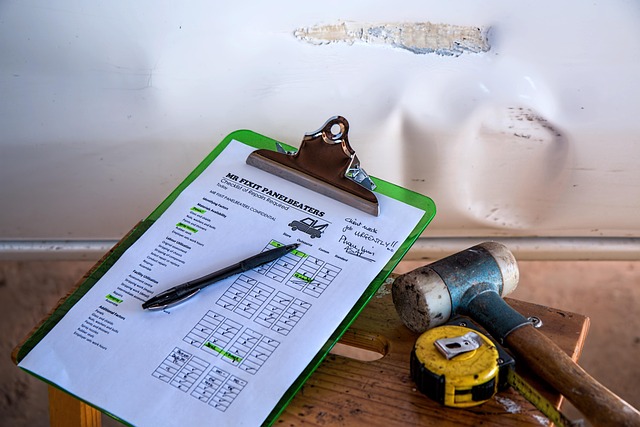

After a fiberglass collision restoration, ensuring quality assurance is paramount to guarantee longevity and optimal performance of the repaired vehicle. Skilled technicians employ meticulous inspection processes, utilizing specialized tools to detect even the most subtle imperfections. Every angle and surface is carefully evaluated, from checking for proper alignment and fit to examining the integrity of the fiberglass resin. This rigorous standard ensures that any issues are addressed before the final touch-ups, resulting in a repair that not only looks but also performs like new automotive body work.

The focus on quality doesn’t stop at visual inspection; it extends to functional testing as well. Automotive repair services for fiberglass damage require a deep understanding of material properties and the unique challenges posed by these composite materials. By simulating real-world conditions, technicians ensure that the repairs withstand the stresses of daily driving, preventing future car damage repair issues. This commitment to excellence ensures that owners can confidently take their vehicles on the road, knowing their investment is protected by top-tier fiberglass repair collision services.

After a thorough understanding of fiberglass composition and effective inspection techniques, it’s crucial to emphasize quality assurance for lasting fiberglass collision repair. By combining visual and functional assessments, shops can ensure that every repair meets or exceeds industry standards. This multifaceted approach not only guarantees the structural integrity of vehicles but also safeguards customer satisfaction in the long term, ensuring that repaired vehicles perform as good as new on the road.